Wá kí o sì kọ́ nípa HSS

Irin oníyára gíga (HSS) jẹ́ irin irinṣẹ́ tí ó ní agbára gíga, agbára ìfaradà gíga àti agbára ìfaradà ooru gíga, tí a tún mọ̀ sí irin afẹ́fẹ́ tàbí irin mímú, èyí tí ó túmọ̀ sí wípé ó le kódà nígbà tí afẹ́fẹ́ bá tutù nígbà tí a bá ń pa á, ó sì le. A tún ń pè é ní irin funfun.

Irin iyara giga jẹ́ irin alloy tí ó ní àkójọpọ̀ tó ní àwọn èròjà carbide bíi tungsten, molybdenum, chromium, vanadium àti cobalt. Iye gbogbo àwọn èròjà alloying dé 10 sí 25%. Ó lè pa líle gíga mọ́ lábẹ́ ooru gíga (ní nǹkan bí 500℃) ní gígé iyara gíga, HRC lè ju 60 lọ. Èyí ni ànímọ́ pàtàkì jùlọ ti HSS - líle pupa. Àti irin erogba nípa pípa àti tempering otutu kékeré, ní iwọn otutu yàrá, bó tilẹ̀ jẹ́ pé líle gíga wà, ṣùgbọ́n nígbà tí iwọn otutu bá ga ju 200 ℃ lọ, líle náà yóò dínkù gidigidi, ní 500 ℃ líle ti dínkù sí ìwọ̀n kan náà pẹ̀lú ipò annealed, ó pàdánù agbára láti gé irin pátápátá, èyí tí ó dín àwọn irin carbon tool gígé irin kù. Àti irin iyara giga nítorí líle pupa tó dára, láti ṣe àtúnṣe àwọn àìlera apanirun ti irin irin erogba.

Irin oníyára gíga ni a sábà máa ń lò láti ṣe àwọn irinṣẹ́ gígé irin tín-tí ...

Wá kí o kọ́ nípa irin tungsten

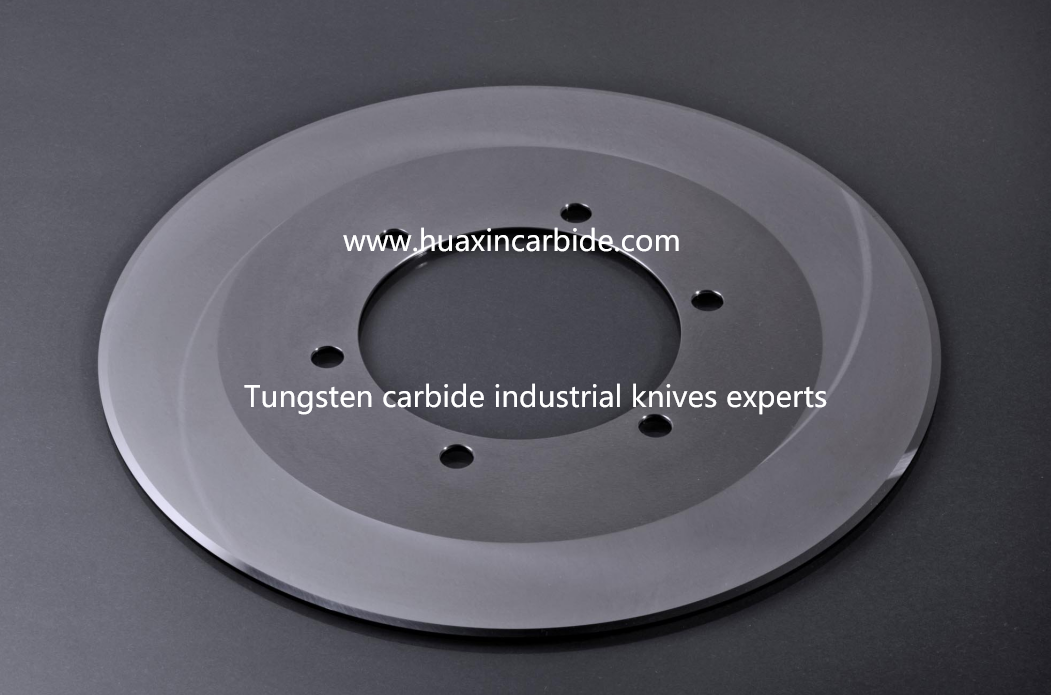

Irin Tungsten (carbide) ní ọ̀pọ̀lọpọ̀ àwọn ànímọ́ tó dára bíi líle gíga, resistance ìfàmọ́ra, agbára àti agbára tó dára jù, resistance ooru, resistance ipata, àti bẹ́ẹ̀ bẹ́ẹ̀ lọ. Pàápàá jùlọ líle gíga àti resistance ìfàmọ́ra rẹ̀ kò yí padà kódà ní iwọn otutu 500℃, ó sì tún ní líle gíga ní 1000℃.

Irin Tungsten, tí àwọn èròjà pàtàkì rẹ̀ jẹ́ tungsten carbide àti cobalt, jẹ́ 99% gbogbo àwọn èròjà àti 1% àwọn irin mìíràn, nítorí náà ni a ṣe ń pè é ní irin tungsten, tí a tún mọ̀ sí carbide tí a fi símẹ́ǹtì ṣe, a sì kà á sí ohun tí ó jẹ́ eyín iṣẹ́ òde òní.

Irin Tungsten jẹ́ ohun èlò àdàpọ̀ tí a fi irin ṣe tí ó ní ó kéré tán ìdàpọ̀ irin carbide kan. Tungsten carbide, cobalt carbide, niobium carbide, titanium carbide, àti tantalum carbide jẹ́ àwọn èròjà tí ó wọ́pọ̀ nínú irin tungsten. Ìwọ̀n ọkà ti èròjà carbide (tàbí ìpele) sábà máa ń wà láàárín 0.2-10 microns, àti àwọn èròjà carbide ni a máa ń so pọ̀ nípa lílo ohun èlò ìsopọ̀ irin. Àwọn irin ìsopọ̀ náà sábà máa ń jẹ́ irin ẹgbẹ́, tí a sábà máa ń pè ní cobalt àti nickel. Nítorí náà, àwọn irin tungsten-cobalt, àwọn irin tungsten-nickel àti àwọn irin tungsten-titanium-cobalt wà.

Ohun tí a fi ń ṣe àgbékalẹ̀ síntíntìntì ni láti tẹ ìyẹ̀fun náà sínú bíllet, lẹ́yìn náà kí a fi sínú iná ààrò láti mú un gbóná dé ìwọ̀n otútù kan (iwọ̀n otútùntì ...

①Tungsten àti kobalt tí a fi simenti ṣe

Ohun pàtàkì ni tungsten carbide (WC) àti binder cobalt (Co). Ìpele náà jẹ́ “YG” (“líle, cobalt” nínú Hanyu Pinyin) àti ìpíndọ́gba iye cobalt lápapọ̀. Fún àpẹẹrẹ, YG8, èyí tí ó túmọ̀ sí WCo lápapọ̀ = 8% àti ìyókù ni tungsten carbide tí a fi simenti ṣe.

②Tungsten, titanium àti kobalt tí a fi simenti ṣe

Àwọn èròjà pàtàkì ni tungsten carbide, titanium carbide (TiC) àti cobalt. Ìpele náà jẹ́ “YT” (“líle, titanium” nínú Hanyu Pinyin) àti àròpín akoonu titanium carbide. Fún àpẹẹrẹ, YT15, túmọ̀ sí àròpín TiC=15%, ìyókù jẹ́ tungsten carbide àti àròpín cobalt nínú tungsten titanium cobalt carbide.

③Tungsten-titanium-tantalum (niobium) carbide

Àwọn èròjà pàtàkì ni tungsten carbide, titanium carbide, tantalum carbide (tàbí niobium carbide) àti cobalt. Irú carbide yìí ni a tún ń pè ní carbide gbogbogbò tàbí carbide gbogbogbò. Ìpele náà ní “YW” (“lile” àti “million” nínú Hanyu Pinyin) pẹ̀lú nọ́mbà ìtẹ̀léra, bíi YW1.

Irin Tungsten ní ọ̀pọ̀lọpọ̀ àwọn ànímọ́ tó dára bíi líle gíga, ìdènà ìfàmọ́ra, agbára àti agbára tó dára jù, ìdènà ooru, ìdènà ìbàjẹ́, àti bẹ́ẹ̀ bẹ́ẹ̀ lọ. Pàápàá jùlọ líle gíga àti ìdènà ìfàmọ́ra rẹ̀ kò yí padà kódà ní ìwọ̀n otútù 500℃, ó sì tún ní líle gíga ní 1000℃. A ń lo carbide tí a fi símẹ́ǹtì ṣe àwọn ohun èlò, bíi irin ìyípadà, irin ìlọ, àwọn irin ìgbì, àwọn irinṣẹ́ tí ó máa ń súni, àti bẹ́ẹ̀ bẹ́ẹ̀ lọ. Ìyára gígé carbide tuntun dọ́gba pẹ̀lú ọgọ́rọ̀ọ̀rún ìgbà ti irin carbon.

Àkókò ìfìwéránṣẹ́: Feb-21-2023